After completing a series of preliminary work for supplier screening, including confirming the supplier's ability to manufacture the products with the specifications you need, obtaining a satisfactory quotation, and preliminary verification of whether the manufacturer has the ability to meet the regulatory compliance requirements of your country and market (regarding the precautions and risk mitigation methods for these processes, if you are not very familiar with them, please refer to my previous articles for a detailed introduction), I believe that at this point, you already have one or more satisfactory manufacturers in mind, and everything seems to be going smoothly.

What are you waiting for? Can't you wait to put your design and brand concepts that have already cost you a long time and effort, with promising market prospects, into actual product production? Then quickly push them to the market and convert them into a continuous stream of profits, so that you can reach your dream of success as soon as possible!

However, I suggest you be patient, because things are far from as simple as what you have seen so far! Because the risk management challenge you are facing is just beginning. Because you should know that behind the vast majority of manufacturers of finished products, there are usually very complex and ever-changing supply chain systems hidden, which means that the risk management work for your procurement and supply chain is also extremely complex and challenging, and it should be a continuous systematic work, especially in China, the biggest and most complex supply market in the world.

So, when you think everything is going well, it is often the most worrying moment because the work you have done before is only a part of the preliminary foundational work in the complex supplier screening system workflow. And the more challenging risk management work that truly plays a decisive role in your successful establishment of a stable and secure supply chain in China has just begun. However, don't worry; although there are still many potential risks ahead and there will be many difficulties in effectively avoiding these risks, please believe that with more than ten years of practical experience in international procurement and supply chain risk management, I will provide you with as detailed and comprehensive an analysis as possible of the risks and challenges you may encounter in the future and provide you with effective suggestions. I will do my best to help you avoid or minimize the risks and challenges that may cause losses to your business and brand.

The following sample production process is very important and the first step in verifying the true capabilities of the manufacturers that have been preliminarily selected by you.

Before starting this process, there is also a very important note, which is that unless there is only one manufacturer in the entire China capable of producing and supplying your product (of course, given the strong capabilities of China's supply chain foundation, the probability of such a situation is generally small), I generally recommend selecting at least 2-3 manufacturers for sample production work of your product in the preliminary sourcing and screening process. Even if the cost of sample production is very high, your budget is limited, and you can only afford the cost of sample production from one manufacturer, there are still some corresponding solutions (which I will explain in detail in the following article). I also recommend that you have at least 2–3 suppliers as a reserve base.

As for why it is necessary to choose at least 2-3 manufacturers that have undergone initial screening and are qualified for your production samples, As I mentioned earlier, what was done before starting sample production was only a basic part of the complex supplier screening work, and at this point, you are not sure whether the so-called qualified suppliers selected are truly capable of meeting your product quality requirements. And the supplier sourcing and screening work you did before was like the initial interview in human resources department recruitment, requiring further re-examination and other work before selecting the winner. And your sample production is just like a retest process, so you need to select the winner from at least 2–3 manufacturers who have entered the retest. Therefore, it is important to remind you not to expect that the manufacturers you initially selected are truly capable of meeting your requirements perfectly and becoming important supply partners that will affect your product quality, market profit, and brand reputation in the future. It is still too early to draw conclusions at this time, as we have more important supplier screening and risk prevention work to do in the future. You need to be very cautious.

So, after determining the manufacturers you want to collaborate with for sample production, you need to pay the relevant fees and invest them in the sample production process. Now, let me provide you with a detailed introduction to some important precautions and potential risks during this process, as well as methods to avoid these risks, in order to successfully complete the sample production and confirmation process.

Firstly, before officially starting your sample production, please double check with the manufacturer all clear and accurate documents related to your products, including the product specification sheet, product design drawings, accurate regulatory compliance requirements, etc., to ensure that no details are missed before the start of sample production.

Secondly, please note that if the documents you send to suppliers contain any trade secrets or copyrighted information, especially for OEM products, it is recommended that you sign a confidentiality agreement with the manufacturers before sending these 3D design drawings and other documents related to your products to ensure that your legitimate rights and interests, such as copyright, are not infringed upon.

Although the current laws in China are increasingly strict in regulating illegal commercial activities such as counterfeiting and copyright theft, it is sometimes inevitable that products designed by customers are ultimately plagiarized by some manufacturers for their own products to obtain illegal profits. In my 13-year career, I have seen many clients suffer from the painful lessons of not signing a confidentiality agreement and being robbed of their products or brand copyright, resulting in huge losses from market profits, brand reputation, and even administrative penalties. Therefore, it is necessary to sign a confidentiality agreement with the manufacturers who will produce your samples in advance. In addition, their attitude towards your proposed confidentiality agreement for design drawings, copyrights, etc. can indirectly reflect the potential risks that they may bring to you in terms of commercial credit in the future. (Of course, commercial credit risk assessment is another extremely important task in supplier screening, and I will provide you with a detailed explanation in a special article.)

Next, after signing the confidentiality agreement and re-confirming all the detailed requirements of your product with the manufacturers, there is still another important step that you have to draft and sign a formal sample order agreement with them. Because, as far as I know, a large number of suppliers usually do not proactively offer and sign sample order agreements with customers but only provide an electronic version of the sample PI, which simply indicates basic information such as your product specifications, sample costs, production time, supplier's payment account information, etc. Apart from this, there are almost no terms that consider your interests and risk perspectives. Therefore, we need to proactively manage risks in the sample production process ourselves. One of the best ways is to draft a comprehensive sample order agreement and send it to your suppliers, requiring them to confirm and sign or stamp on it, in order to help you avoid or reduce the risks and losses you may suffer in the event of sample production failure or other legitimate interests being infringed on in the future.

Although the process of drafting, negotiating, and signing contracts with bulk orders is relatively simple and much easier, the importance of a sample order agreement cannot be ignored. Generally speaking, the main clauses should include the following aspects:

Firstly, the terms regarding the overall description of your sample production order, which include sample quantity, sample price, mold cost (if any), and a description of product specifications and parameters, etc.

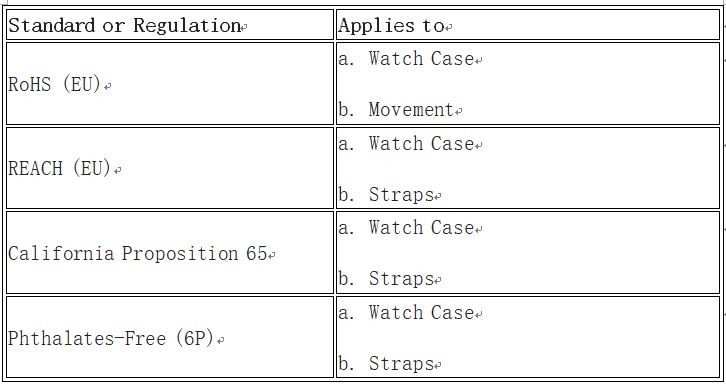

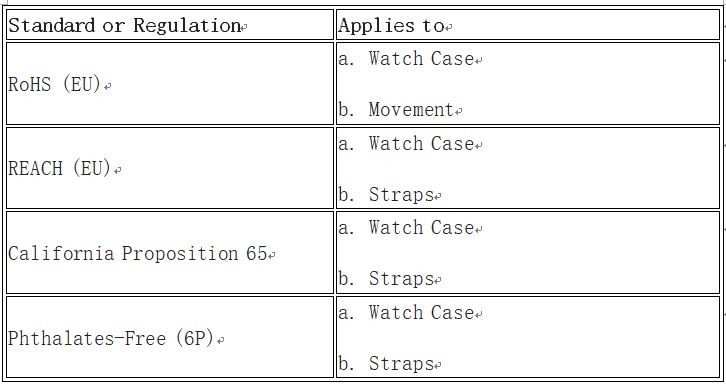

Secondly, the samples produced must meet the product safety standards and regulatory compliance requirements in your country and market. It should be noted that different products have different requirements, and it is even possible that different accessories on the same product require different standards and regulations. Taking the wrist watch product of one of my French customers as an example, as you can see in the table below, the standards required for watch cases, movements, and straps vary. Therefore, it is best for you to provide a clear and accurate description in the sample order agreement.

Thirdly, regarding the terms of requiring manufacturers to provide the design concept files for your products, which are used in sample production, perhaps you find it strange that there are already documents from you, such as specifications and design drawings, so they can't directly produce samples according to the requirements. Why do we still need to do repetitive work?

If you have some experience and understanding of the manufacturer's production process, you should know that no matter how perfect and detailed your design drawings files are, before putting them into production, manufacturers usually have their product engineers create Product Design Concept files that are suitable for their internal systems and production processes based on the product design drawings or specifications you have provided, and many errors or misunderstandings in the details that lead to the failure of sample production often occur in this step. The reason why the supplier needs to provide those product design concept files is to check again whether the manufacturer's personnel responsible for sample production (rather than the sales personnel you contacted online) understand your product specification requirements or product design drawings accurately, to reduce the probability of sample production errors or failures.

Once again, you need to be vigilant against potential errors and risk events at any time, especially during peak production seasons when their production departments are likely to produce samples for other customers at the same time, and they also have many large orders to urgently produce and deliver. Because at this time, some manufacturers often do not pay as much attention to sample production as they do to mass orders, because sample production does not necessarily guarantee profits for them (unless your company is big and your brand is very famous, although their production lines are already very busy, they are still willing to spend much time and do their best to produce satisfactory samples in order to secure your future large orders).

Therefore, I suggest that you should be vigilant at all times and take the initiative to avoid errors and risks that may occur at any time during the sample production process. Therefore, it is important to pay attention to those small details.

Firstly, regarding the protective clauses for your legitimate rights and interests after the complete failure of the sample production, although you have repeatedly confirmed all the details and requirements regarding your product specifications and other aspects with the manufacturers before making the samples, is that enough to ensure that there is no problem? The answer, of course, is no. In my experience, it is not recommended for customers to expect the supplier to produce a perfect sample according to their requirements the first time, as such results often disappoint them.

And I often hear some customers complain that the suppliers who made the samples for them still failed to meet their requirements after several attempts, and even later they refused to continue producing samples for customers until they met their requirements, especially during the peak production season, citing the production line being too full and unable to arrange time. In addition, those suppliers also refuse to refund the sample production fees and mold fees previously paid by customers, or they may require customers to pay these fees again before continuing to produce samples. Why did such problems arise?

The reason for this is that, except for same cases where the customers constantly changed the Product Specification during the sample production process, I have seen more cases where many customers did not sign sample production agreements with manufacturers before the official start of sample production, or there were no guarantee clauses in the signed agreements regarding compensation for losses caused to customers due to sample production failures, This leaded to manufacturers directly refusing to continue producing more samples for customers after a few unsuccessful attempts, or finding various reasons to indefinitely extend the production time of customers' samples, resulting in customers wasting their initial investment time and funds but being helpless, thus lost their good market opportunities.

Therefore, in order to avoid the above risks and potential consequences for you, I strongly recommend that, before engaging in formal sample production cooperation with the manufacturers you have chosen, you sign a sample order agreement with them and negotiate with them in the contract to include the following clauses that fully protect your legitimate rights and interests:

The production time of the first sample, as well as the production time of the second and third samples (usually shorter than the first sampling time cycle), if the first sample production fails, is very low. Especially for OEM products, the probability of the supplier presenting you with a sample that fully meets your requirements for the first time is very low, so please prepare in advance for the possibility of further sampling for optimization.

If the manufacturer fails to produce samples that meet the specifications and quality requirements you have already determined in the early stages due to their own reasons, the supplier has no right to demand that you pay the sample production fee again. (Of course, if you request to change product specifications during the process, which results in increased costs, we will negotiate separately.)

The definition of the final failure of the sample production declaration as well as compensation terms such as refunds after failure After the first failure of the supplier, although they may promise to continue producing samples for you until the requirements are met, losing time means losing valuable market opportunities and profits, so there is no need to waste your time on those who are not excellent suppliers and endless waiting. Therefore, it should be specified in the contract that the number of failed samples is defined as complete failure (usually 2 or 3 times depending on the complexity of your product), and the supplier should fully or partially refund the sampling fee you paid after reaching the number of failures defined in the contract to minimize the losses you may incur as a result (for cases where partial refund of sampling fees is mainly for special cases that require mold opening, which I will explain in detail later), so that you can quickly transfer to the next alternative supplier for sample production work until you receive satisfactory samples. This is also why I suggested earlier that it is best to choose 2–3 suppliers for sampling at the same time or as alternative reserves.

Regarding the terms of sample production subcontracting, it is required that the supplier's samples be produced in their own production workshop to avoid breach of contract. What is the reason for doing this?

I have encountered several cases where customers initially chose manufacturers who were not able to meet their requirements but told the customers that there was no problem producing the products. Then they changed the role to become intermediaries and handed over customers' orders to other manufacturers they knew to produce in order to earn intermediate price differences or commissions. And they sold and exported the products to customers under their own company's name after they were produced.

Unfortunately, many customers did not know the truth and had been deceived for a long time. Moreover, if customers’ orders encountered problems during the production process of bulk goods or after receiving the goods, those manufacturers (actually intermediaries) would shift the responsibility entirely to the factories that actually produced the products. However, because the customer had never communicated with or contacted those factories, many customers found it difficult to maintain their legitimate rights and interests in a timely manner, ultimately causing their business and brand reputation to suffer serious negative impacts among their own consumers.

In addition, there is another important aspect of production subcontracting, which is the risk prevention issue of subcontracting for mass orders. I will provide you with a detailed introduction in the special article on procurement agreements and risk prevention for mass orders in the future.

Regarding the terms of mold and tool ownership, especially for the many OEM products, even during the sample production stage, it may be necessary to open a mold, and the cost of mold and tooling is often expensive, and the production time is also relatively long. In addition, it also involves your copyright protection issues. Therefore, once the supplier's sample production is ultimately defined as a failure, you need to choose another manufacturer to continue. So ensuring your ownership of mold and tooling will bring you the following benefits:

Save your money and time. Most of the time, these molds are universal, so when you change suppliers, the molds produced by previous suppliers can often be reused, and only minor adjustments may be needed to avoid the cost and time waste of reinvesting in mold production.

Protect your intellectual property from infringement. Ensuring your ownership of mold and tooling also protects the products you have worked hard to design from illegal infringement by some unscrupulous manufacturers, resulting in losses to your market profits and brand reputation. After all, based on my experience, legal protection of intellectual property rights in cross-border trade is an extremely complex and lengthy process, and the final outcome is unknown, so it's best to be cautious. How can the mold and tooling and intellectual property rights that are put into production after the supplier's sample production is successful be protected? I will also provide you with a detailed introduction to this in a special article on risk prevention for procurement agreements and mass production.

Alright, that's an overview of the hidden risks and avoidance methods during the sample production process. Of course, depending on the different categories of products and the actual needs of your procurement, some details that need to be noted during the process and the specific terms in the sample production agreement may vary.

Therefore, if you have any further questions, ideas, or suggestions regarding this aspect, or if you need any assistance, please let me know.

Author: Wesley Liu (Founder of ProcurementInChina.com, Leader of Procurement & Supply Chain)